1.Choosing equipment with sound mechanical performance, the saw with sharp edge and thickness 1.5mm-2.2mm. Before every cutting, you should note to grind the edge of saw blade with firebrick for duration not less than 15 minutes. The diameter of chosen saw rangers is about 350mm-400mm (special saw blade is better).

2.Paying attention to the cutting speed during cutting slabs, and normal speed shall be 2.5m/min to 5m/min; when the blade is cutting into and taking off from the slab. It need keep in a low speed and avoid slab edge or border; the rotate speed of cutter and main blade shall be around 2500rpm. Higher RPM would have a better cutting effect.

3.When the cutting-tiles which are smaller than 1000*1000mmm, be sure the tile are steady on the cutting machine. Swaying of the tiles would cause damages when cutting.

4.The well-cut slabs shall be separated by pearl cotton in deposit, to avoid being damage.

5.The tiles shall be processed by using the machining of border grinding and edge rounding, which glass straight grinding machine maybe used. During slab grinding, please note the force that each grinding head bears, and grinding/cutting volume of each emery wheel shall not be over 1mm. Keeping the main strap of grinding machine being in accordance with slab-in strap horizontal, otherwise, unevenness will occur to the slab. Grinding wheel shall be used for the edge/border polishing. If not available portable water grinder may be used.

6.In heteromorphic table machine or water basin hole drilling, please choose Φ35 glass aiguilles, and mark the outline of the hole, the drill several small holes around the hole with stone materials or glass dedicated aiguilles; be noted to drill holes at four corners with cooling water being used. At the same time, the cutting blade shall be well ground on the firebrick for operation; operation gently in cutting; if the slab cannot be wholly separated in one cut, please cut with several come-and-goes and cooling water being used. Dry-grinding shall be avoided to prevent slab from broken.

7. In arc border rounding, please mark it at first and form the outline with hand grinder, then polish it with portable water grinder, with operation method the same with that of other stone materials. What shall be noted is that dry-grinder is to be avoided and water cooling being applied in polishing. In border thickening, both surfaces to be joined shall be roughed with grinder, and then be cleaned. For French border machining, cut the line out from the cutter at first, then grinder with above method, and the optimal effect will be obtained.

8.For 45。 back beveling, the gradient of the main blade on the cutter shall be adjusted by hand, and the working table shall be cleaned, then adjust position slab. It is better that a layer of rubber be placed on the working table, then put slab on it to avoid the polished surface being scratched; prior to machining, saw shall be ground and water level shall be checked, and keep a slow speed in operation.

9.Processing stairs and drilling skid proof grooves: the stair shall be thickened, edge-round and 45。angle, with the operation illustrated in item 6 and 7 being followed. Pay attention to the rubber be placed of heteromorphic slab. It is better that back-cutting be used for the border cutting and follow client’s requirement in skid proof groove forming. During groove forming, hand turning border cutter shall be used, and groove width and depth shall be well adjusted, and saw blade (in 2.4mm thickness) be chosen according to the width; generally, install 2 saw blades on the machine, and shall add/reduce saw blades based on the groove sizes; the form groove shall be polished the portable water grinder.

10.Processing the slot of dry hanging plate, it shall use the fixed plate on the countertop of hand-operated edge cutter, and clamp the slab to be machined vertically, then adjust the working table, and add saw blades according to the width of trough.

11.Handling carefully in finished products deposit; stack them vertical and do not stack too much at a single place to prevent slabs from being damage.

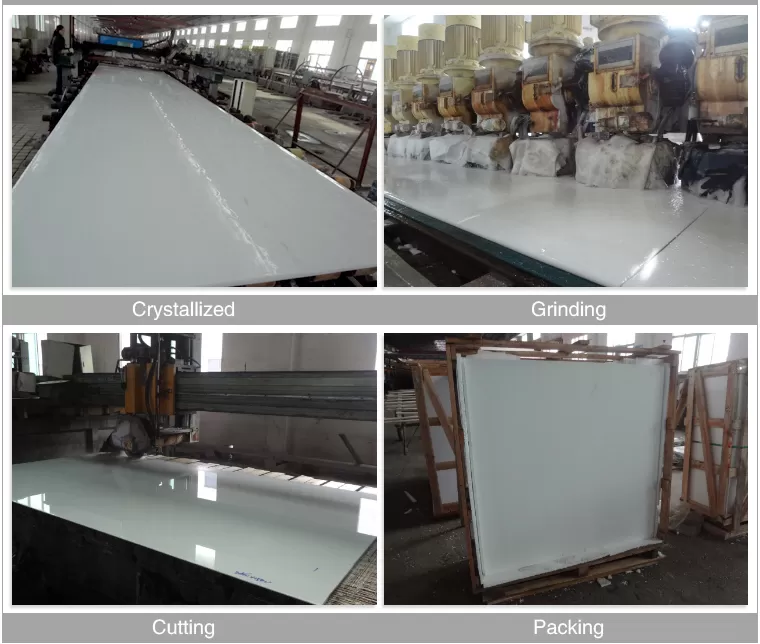

GOLDENPHOENIX STONE decades of experience in crystallized glass industry, we are specialized in production of ‘green material,Nano Glass & Crystallized Glass Panels.We specialized in manufacturing of

GOLDEN PHOENIX STONE is one of leading stone manufacturer and exporter in South China with 16 years' history. Locate at south of china of Fujian Province, who has own granite quarries & factories established in early 2002, surrounding area which famous for its abundant Chinese stone sources and stone processing culture. We have 300m2 showroom and 5000m2 factories in ShuiTou, Quanzhou, Fujian; thousands tos blocks materials in stock and equipped with complete series facilities. Meanwhile we own five quarries: Jade white marble, China black granite, Travertine and Beige marble. Chinese traditional carving techniques perform the unique glamour of stone culture. Our carving factories have totally more than 100 craftsmen with rich experience in carving industry. We have 50 containers' capaci

We are a professional manufacturer of Nano Crystallized Stone from China. Nano Crystallized stone and Artificial Quartz Stone are unique products which superior to natural stone

GOLDEN PHOENIX STONE is a professional stone manufacturer and exporter which was established by those people who have more than 16 years' experience in stone industry. GOLDEN PHOENIX spe